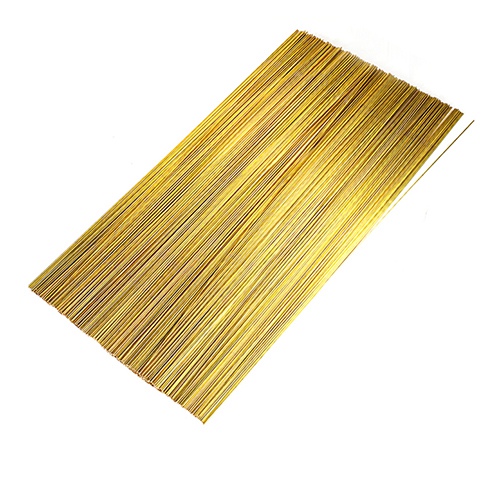

Brazing Material for Copper is silvery white and can be formed into various forms, including wire, strips, rings, powder, and ribbon, depending on process requirements. Primarily composed of silver, copper, and zinc in appropriate proportions, it is a high-performance metal material specifically designed for brazing copper and copper alloys.

Brazing Material for Copper exhibits strong wetting properties on copper surfaces, rapidly spreading to form uniform joints during the brazing process. Its wetting angle is ≤30°, resulting in high weld continuity and significantly improving weld yield. These excellent wetting properties reduce the risk of weld defects such as cold and hollow joints.

Standard silver-based alloys have a melting point range of 640°C to 680°C. Compared to traditional copper-phosphorus alloy brazing filler metals, this material operates at lower temperatures, reducing the risk of thermal damage to the base metal. It is suitable for brazing heat-sensitive components, extending product life, and reducing the risk of deformation.

The brazed joint achieves a tensile strength of up to 420 MPa, fully meeting the structural strength requirements of high-pressure applications such as refrigeration equipment and automotive heat exchangers. The joint is dense, crack-free, and exhibits excellent fatigue resistance.

The silver-containing brazing filler metal forms a dense bond layer on the copper surface, providing strong resistance to oxidation and corrosion. No visible corrosion spots were observed after 72 hours in a salt spray environment at 95% relative humidity. It is particularly suitable for medium- and long-term use in HVAC, air conditioning, and medical equipment.

Brazing Material For Copper is widely compatible with not only pure copper but also copper alloys such as brass and bronze, creating high-quality welds between various copper components. Users can choose from a variety of composition grades to accommodate diverse alloy systems.

Brazing Material For Copper complies with EU environmental regulations such as RoHS and REACH, and does not contain harmful elements such as cadmium, lead, and mercury, making it suitable for export to Europe, the United States, Southeast Asia, and other regions. The brazing process emits low volatiles, which helps protect worker health and workplace environmental standards.

In Gree household air conditioner copper tube assemblies, Brazing Material for Copper is used for brazing connections between refrigeration pipes, ensuring system tightness and high-pressure resistance. The welded copper tubes are leak-proof, significantly improving operational reliability and boosting overall unit energy efficiency.

Haier refrigerators utilize copper tube condensing systems. Brazing Material for Copper is primarily used for splicing the pipes in the condenser and evaporator components. Its high ductility enables the plant to employ automatic wire brazing, improving production efficiency and reducing the rate of false welds.

In new energy vehicle battery cooling modules, Brazing Material for Copper is used for connecting high-precision copper heat pipes. It meets the stability requirements of EV systems in high-temperature and vibration environments, effectively extending the life of the heat exchange system.

In high-precision medical equipment from companies like Mindray, Brazing Material For Copper is used to connect critical sensor pipes and copper interfaces. Its minimal weld seams and high strength prevent contamination risks, ensuring the stability and security of medical data acquisition systems.

During the installation of hot and cold water piping in high-end hotels, Brazing Material For Copper is used to braze copper pipes together, providing a long-lasting seal and resistance to scale corrosion. Compared to traditional soldering, it increases service life by over 30% and significantly reduces maintenance costs.

The collector copper tube modules produced by Sunrain Company are connected using Brazing Material For Copper. Its high-temperature resistance and excellent thermal conductivity ensure the continued stable operation of solar systems under intense sunlight.

International heat exchanger manufacturers such as SWEP use Brazing Material for Copper (Brazing Material for Copper) for multi-point connections between copper sheets and copper tubes. Compatible with vacuum brazing processes, the brazed product can pass pressure tests exceeding 15 MPa and is widely used in thermal energy equipment export projects.