silver copper brazing rod is a slender cylindrical brazing filler metal rod made from an alloy of silver, copper, and other elements. It is primarily used for high-strength and precision metal joining applications and is a medium- to high-temperature brazing material.

Silver Copper Brazing Rod offers excellent metal bonding strength, with brazed joint strength exceeding 85% of the parent metal, making it particularly suitable for joining high-voltage components. For example, Ag15CuP alloy boasts a shear strength of 400 MPa, making it suitable for applications requiring stringent joint strength.

Silver Copper Brazing Rod exhibits excellent wetting and flowability during brazing, effectively filling tiny gaps and creating dense, uniform welds. Ag25Cu alloy exhibits excellent melt flow starting at around 700°C, making it particularly suitable for welding complex components.

The Silver Copper Brazing Rod boasts precise melting point control. Common Ag15Cu alloys have a melting point range of 640-800°C. This allows for precise temperature control during brazing, preventing overheating and damage to the base material or thermal deformation. It is particularly suitable for the electronics manufacturing industry, where heat-affected zone (HAZ) control is critical.

Due to the inherently excellent oxidation resistance of silver and copper, the brazed weld exhibits superior corrosion resistance under normal operating conditions, making it particularly suitable for outdoor air conditioning copper pipe welding and marine equipment manufacturing, extending overall service life.

Some grades, such as the Ag5CuP alloy, contain phosphorus, eliminating the need for additional flux when brazing copper materials. This simplifies the process, improves efficiency, and reduces residual pollution, resulting in improved environmental protection and energy savings.

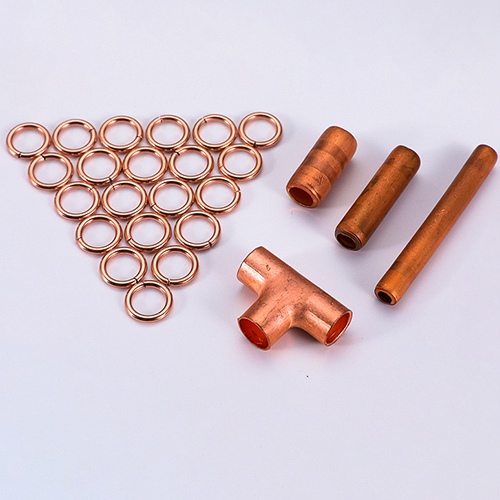

In the air conditioning manufacturing industry, Silver Copper Brazing Rods are widely used for automated brazing of copper refrigeration pipes, particularly for connecting refrigerant copper pipes between outdoor and indoor units. Its high thermal conductivity and strength ensure system sealing and prevent refrigerant leaks.

Many automotive parts manufacturers use Silver Copper Brazing Rods to connect copper radiator tubes to aluminum components. Its excellent corrosion resistance and thermal fatigue performance enhance the reliability of vehicle cooling systems. It is widely used in Toyota and Honda's Tier 1 supply chain factories.

Repair service companies use Silver Copper Brazing Rods to efficiently repair copper connections in refrigerators, freezers, and industrial chillers. Because they require no flux and produce aesthetically pleasing solder joints, they are particularly well-suited for quick, on-site repairs by skilled workers.

In electronics manufacturing plants, Silver Copper Brazing Rods are used to connect copper components such as sensitive device housings and conductive terminals, maintaining stable contact resistance and uniform solder joint strength. They are suitable for use by contract manufacturers for high-end electronics brands such as Siemens.

Some metal artists and sculpture studios use Silver Copper Brazing Rods to seamlessly join copper sculptures. Its bright silver weld is not easy to change color and is suitable for welding processes that require high decorative effects.

Previous: