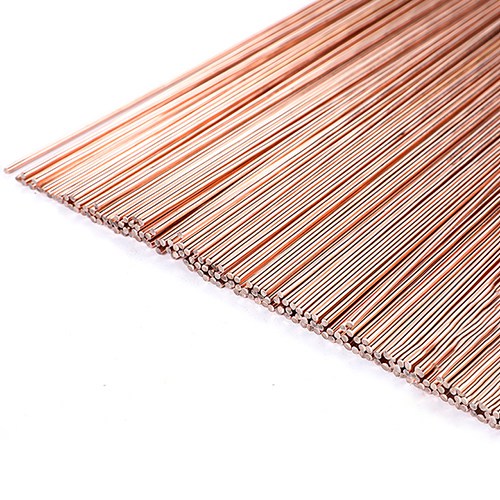

Copper Phosphorus Solder is a solder used for welding copper and its alloys, usually available in rod, wire or ribbon form. In modern industrial manufacturing, Copper Phosphorus Solder has become the preferred material of many manufacturers and engineers due to its excellent welding performance and wide range of applications. It is suitable for joining a variety of metal materials.

| BrazingAlloys | AWS | Chemical Composition(%) | Solidus | Liquidus | Main Uses | |||||||

| Ag | Cu | P | Zn | Sn | Other | F | ℃ | F | ℃ | |||

| BCu93P | BCuP-2 | / | 93 | 7 | / | / | / | 1310 | 710 | 1460 | 795 | Suitable for copper and copper alloy,with good fluidity. |

| BCu86P | / | / | 86 | 7 | / | 7 | / | 1134 | 657 | 1270 | 687 | Mainly used for brazing of hard alloy cutter |

| BCu91PAg | BCuP-6 | 2 | 91 | 7 | / | / | / | 1190 | 645 | 1450 | 785 | Mainly used for brazing ferrous metals, nickel-based alloys and Cu-Ni alloys; it has good fluidity. |

| BCu89PAg | BCuP-3 | 5 | 89 | 6 | / | / | / | 1190 | 645 | 1325 | 720 | |

| BCu88PAg | BCuP-4 | 6 | 86.7 | 7.3 | / | / | / | 1190 | 645 | 1275 | 690 | |

| BCu80PAg | BCuP-5 | 15 | 80 | 5 | / | / | / | 1190 | 645 | 1300 | 705 | |

| BCu75PAg | BCuP-6 | 18 | 75.5 | 6.5 | / | / | / | 1190 | 645 | 1190 | 645 | |

Low Melting Point

Copper Phosphorus Solder has a relatively low melting point, usually between 710°C and 890°C. This low melting point property minimizes thermal stress and deformation during welding, and is particularly suitable for welding heat-sensitive components.

Self-wetting

Copper Phosphorus Solder contains phosphorus, which acts as a flux during the welding process, which can reduce the need for additional flux during welding. This self-wetting property makes the welding process easier and reduces the cleaning work after welding.

Good fluidity

Copper Phosphorus Solder has good fluidity and can flow into welds with small gaps. This property makes it particularly suitable for welding closely fitting parts, ensuring the integrity and strength of the welded joint.

Corrosion Resistance

Joints welded with copper phosphorus solder have good corrosion resistance, especially in non-sulfur environments. This makes it an ideal choice for many industrial applications, especially where long-term stability is required.

Multiple Alloy Options

Copper Phosphorus Solder offers a variety of alloy options, including silver-containing and non-silver-containing alloys. Silver-containing alloys generally have better fluidity and toughness, suitable for applications that require higher strength and durability.

Electronic Industry

In the electronics industry, Copper Phosphorus Solder is used to weld copper circuit boards and electronic components. Its low melting point and good fluidity allow it to precisely connect small electronic components while reducing thermal damage.

Automobile Manufacturing

In automotive manufacturing, copper phosphorus solder is used to weld copper pipes and fittings. Its high strength and corrosion resistance ensure the reliability of automotive cooling and braking systems.

Household appliances

In the manufacture of household appliances, copper-phosphorus solder is used to connect copper pipes and components. For example, in the manufacture of refrigerators and air conditioners, it is used to weld copper pipes to ensure the sealing and durability of the refrigeration system.

Aerospace

In the aerospace field, copper-phosphorus solder is used to weld high-precision copper alloy parts. Its good fluidity and high strength enable it to meet the strict material requirements of the aerospace industry.

Construction industry

In the construction industry, copper-phosphorus solder is used to weld copper pipes and decorative parts. Its corrosion resistance and aesthetics make it an ideal choice for building decoration and water supply and drainage systems.

Daily cleaning

The cleaning of Copper Phosphorus Solder is relatively simple. After welding, wipe the welding area with a damp cloth to remove residual flux and stains. For difficult-to-clean areas, a soft brush can be used for local cleaning.

Regular inspection

Regularly check the integrity and stability of the welded joint to ensure that there are no cracks or looseness. If problems are found, they should be repaired or replaced in time to ensure the safety and reliability of the welded joint.

Protective measures

During cleaning and maintenance, avoid scratching the solder joint with hard objects to avoid damaging its surface. At the same time, avoid prolonged exposure to humid or corrosive environments to prevent rust and corrosion.

Q1: What are the main components of Copper Phosphorus Solder?

A1: Copper Phosphorus Solder is mainly composed of copper and phosphorus, and some alloys also contain a small amount of silver.

Q2: Does this solder require additional flux?

A2: Usually no additional flux is required because phosphorus acts as a flux during the soldering process.

Q3: Is this solder suitable for soldering copper and copper alloys?

A3: Yes, Copper Phosphorus Solder is particularly suitable for soldering copper and copper alloys.