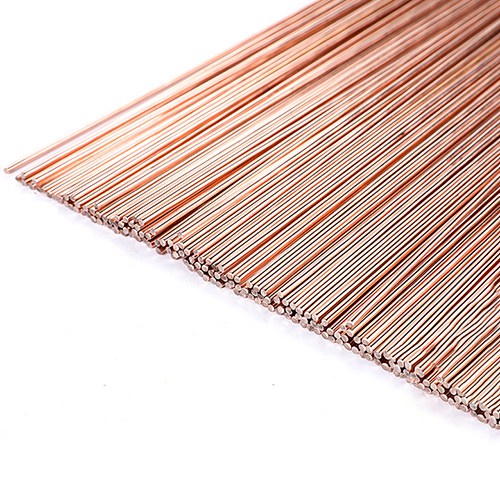

Phosphorized Copper Rod is mainly composed of copper content between 75.5% and 93%, phosphorus content between 5% and 7%, and is in the form of a slender rod. The length and diameter can be customized according to needs. It is a rod-shaped welding material made of high-purity copper and an appropriate amount of phosphorus alloy.

| BrazingAlloys | AWS | Chemical Composition(%) | Solidus | Liquidus | Main Uses | |||||||

| Ag | Cu | P | Zn | Sn | Other | F | ℃ | F | ℃ | |||

| BCu93P | BCuP-2 | / | 93 | 7 | / | / | / | 1310 | 710 | 1460 | 795 | Suitable for copper and copper alloy,with good fluidity. |

| BCu86P | / | / | 86 | 7 | / | 7 | / | 1134 | 657 | 1270 | 687 | Mainly used for brazing of hard alloy cutter |

| BCu91PAg | BCuP-6 | 2 | 91 | 7 | / | / | / | 1190 | 645 | 1450 | 785 | Mainly used for brazing ferrous metals, nickel-based alloys and Cu-Ni alloys; it has good fluidity. |

| BCu89PAg | BCuP-3 | 5 | 89 | 6 | / | / | / | 1190 | 645 | 1325 | 720 | |

| BCu88PAg | BCuP-4 | 6 | 86.7 | 7.3 | / | / | / | 1190 | 645 | 1275 | 690 | |

| BCu80PAg | BCuP-5 | 15 | 80 | 5 | / | / | / | 1190 | 645 | 1300 | 705 | |

| BCu75PAg | BCuP-6 | 18 | 75.5 | 6.5 | / | / | / | 1190 | 645 | 1190 | 645 | |

Phosphorized Copper Rod is known for its excellent flexibility. The rod is not easy to break during processing and bending, and is suitable for welding tasks of complex shapes. Its high tensile strength, combined with the solidus temperature range from 645°C to 1310°C and the liquidus temperature between 645°C and 1460°C, allows structural integrity to be maintained under different thermal conditions. BCuP-5 alloy still maintains good ductility when liquefied at 1300°C, which is convenient for the operator to adjust the welding angle. Flexibility is also reflected in its adaptability to thermal shock, reducing cracks caused by temperature changes, and is particularly suitable for overseas precision manufacturing projects that require fine adjustments.

The energy-saving characteristics of Phosphorized Copper Rod products give them a significant advantage in industrial applications. Their low melting point (BCuP-6 starts to melt at 645°C) reduces the energy required for heating and significantly reduces production costs. The welding efficiency per unit of rod is high, and BCu-3 can melt quickly in the temperature range of 1190°C to 1325°C, reducing heat waste. Energy saving is also reflected in its efficient filling ability, which completes the welding of complex joints in one go and reduces the energy consumption of repeated heating. Especially in large-scale production environments, the energy-saving characteristics have attracted overseas buyers who are concerned about cost-effectiveness and are particularly suitable for energy-sensitive industrial fields.

Phosphorized Copper Rod is known for its excellent fatigue resistance. The joint is not easy to fail under repeated loading and unloading conditions. Its solidus and liquidus temperature difference (BCuP-4 from 645°C to 1275°C) ensures thermal cycling stability. The rod has a uniform microstructure and an impurity content of less than 1%, which reduces the occurrence of fatigue cracks and has a service life of up to thousands of welding cycles. Fatigue resistance is also reflected in its resistance to vibration and shock, which is particularly suitable for equipment that requires long-term dynamic loads. In overseas markets, fatigue resistance makes it the preferred material for heavy machinery and transportation manufacturing.

Phosphorized Copper Rod performs well in the welding of copper joints in power transmission equipment. The solidus of 710°C and the liquidus of 795°C match the thermal characteristics of copper conductors, and the joints have excellent conductivity after welding. Siemens uses this product in its high-voltage power equipment to ensure transmission efficiency and stability, and it is widely used in European power grid construction.

In the welding of copper supports in building structures, Phosphorized Copper Rod is favored for its fatigue resistance and flexibility. BCuP-2 provides a strong joint when it melts at 710°C. ArcelorMittal selected this material in its steel structure projects to ensure the safety and durability of the building, which is particularly popular in the North American construction market.

This product is widely used in the welding of copper parts of industrial pumps, and its energy saving and fatigue resistance are outstanding. BCuP-4 has excellent pressure resistance when it is liquefied at 1275°C. Grundfos uses this product in its pump body manufacturing to ensure the long-term operating reliability of the equipment, which is particularly suitable for the industrial manufacturing field in Asia.

Phosphorized Copper Rod performs well in copper wire welding of communication equipment, and its flexibility and fatigue resistance meet the requirements of high-frequency use. BCuP-5 has stable signal transmission when it melts at 1300°C. Nokia uses this material in its communication base stations to ensure the performance and durability of the equipment, which is particularly favored by the global telecommunications industry.