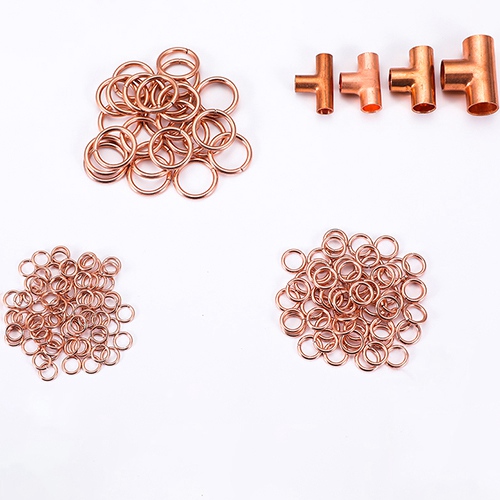

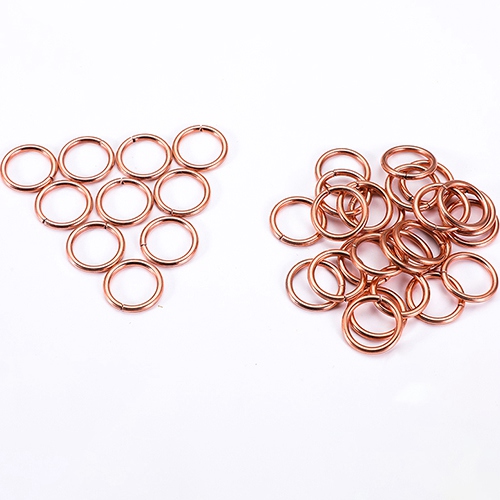

Phosphorus Copper Brazing Ring is made by precision machining. Its core component is copper, which is usually between 86% and 93%, and its phosphorus content is between 5% and 7%. This chemical ratio gives it excellent welding performance. It is a ring-shaped welding material composed of high-purity copper and a small amount of phosphorus. Its appearance presents the unique reddish-brown metallic luster of copper.

| BrazingAlloys | AWS | Chemical Composition(%) | Solidus | Liquidus | Main Uses | |||||||

| Ag | Cu | P | Zn | Sn | Other | F | ℃ | F | ℃ | |||

| BCu93P | BCuP-2 | / | 93 | 7 | / | / | / | 1310 | 710 | 1460 | 795 | Suitable for copper and copper alloy,with good fluidity. |

| BCu86P | / | / | 86 | 7 | / | 7 | / | 1134 | 657 | 1270 | 687 | Mainly used for brazing of hard alloy cutter |

| BCu91PAg | BCuP-6 | 2 | 91 | 7 | / | / | / | 1190 | 645 | 1450 | 785 | Mainly used for brazing ferrous metals, nickel-based alloys and Cu-Ni alloys; it has good fluidity. |

| BCu89PAg | BCuP-3 | 5 | 89 | 6 | / | / | / | 1190 | 645 | 1325 | 720 | |

| BCu88PAg | BCuP-4 | 6 | 86.7 | 7.3 | / | / | / | 1190 | 645 | 1275 | 690 | |

| BCu80PAg | BCuP-5 | 15 | 80 | 5 | / | / | / | 1190 | 645 | 1300 | 705 | |

| BCu75PAg | BCuP-6 | 18 | 75.5 | 6.5 | / | / | / | 1190 | 645 | 1190 | 645 | |

Phosphorus Copper Brazing Ring is known for its high-efficiency welding performance. Its solidus temperature ranges from 645°C to 710°C, and its liquidus temperature ranges from 645°C to 795°C. This feature enables it to reach an ideal melting state in a short time, greatly improving work efficiency. Compared with traditional welding materials, it can achieve uniform melting at lower heat input and reduce energy consumption. For example, BCuP-6 alloy begins to melt at 645°C and completely liquefies at 690°C, which is suitable for fast and mass production environments. The high efficiency is also reflected in its good fluidity, which can quickly fill complex joints, reduce secondary processing time, and provide cost-effective solutions for overseas buyers, especially in the industrial field that pursues production efficiency.

The durability of this product is due to its excellent corrosion and oxidation resistance. The chemical stability of copper-based materials is outstanding in a variety of environments, and the addition of phosphorus further enhances its wear resistance and high-temperature oxidation resistance. The temperature difference between the solidus and liquidus is small (such as BCuP-4 from 645°C to 1275°C), ensuring that it is not easy to crack or deform during repeated heating and cooling. The service life is up to thousands of welding cycles, especially in copper tube and copper alloy connections, and the durability significantly reduces maintenance costs.

Phosphorus Copper Brazing Ring is known for its precision manufacturing process, with dimensional tolerances controlled within ±0.05mm, and the ring structure ensures high fit of the joint surface. The precise ratio of chemical composition, such as 89% copper and 6% phosphorus in BCu-3, ensures the performance consistency of each batch of products. The liquidus temperature range (such as 1325°C to 720°C) allows operation at precisely controlled welding temperatures, avoiding overheating and material waste. Precision is also reflected in its low impurity content (less than 1% of other elements), which reduces pores and defects during welding, providing a guarantee for welding of electronic components or medical equipment with high precision requirements, and is favored by professional buyers.

Phosphorus Copper Brazing Ring performs well in copper pipe welding and is particularly suitable for copper pipe connections in air conditioning and refrigeration systems. Its solidus temperature of 710°C and liquidus of 795°C match the thermal expansion coefficient of copper pipes, and the joint strength after welding can reach more than 90% of the parent material. Carrier and Trane use this product in their refrigeration equipment production to ensure the sealing and pressure resistance of the pipeline system, and it is widely used in high-end air conditioning manufacturing in the North American market.

In ship pipeline welding, Phosphorus Copper Brazing Ring is highly regarded for its corrosion resistance and high fluidity. BCuP-6 alloy melts in the temperature range of 645°C to 690°C and is suitable for the connection of marine copper-nickel alloy pipes. MAN Energy Solutions uses this product in its ship engine cooling system to ensure the long-term stability of the pipe in seawater environment, especially for the customized needs of European shipyards.

This product is widely used in the welding of electronic components, especially for the welding of copper joints of delicate circuit boards. Its precise dimensions and low melting point (such as BCuP-2 solidifies at 1310°C) ensure that thermal damage to sensitive components is minimized. Samsung uses this material in the production of its consumer electronics products to ensure the conductivity and reliability of the welding points, and it is widely used in the electronics manufacturing industry in the Asian market.

Phosphorus Copper Brazing Ring is used in the manufacture of medical devices for the connection of copper components, such as the tubing system of surgical instruments. Its durability and low impurity characteristics (such as BCu-3 other elements less than 1%) meet medical grade standards. Medtronic uses this product in the production of its ventilators to ensure the long-term safety and sterility of the equipment, which is particularly favored by North American medical device buyers.